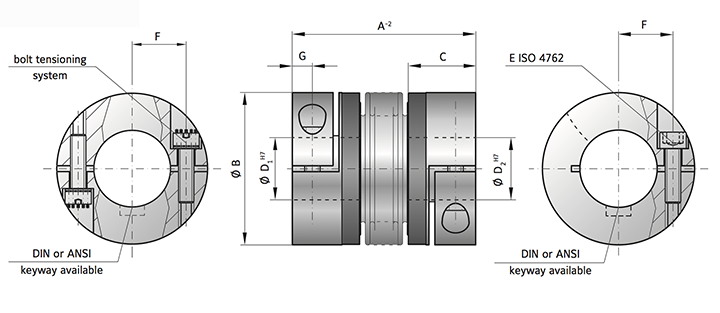

BK2 | Metal Bellows Coupling

The BK2 is designed with a single radial clamping screw per hub (ISO 4762).

Any imbalance of the clamping hubs is compensated for by balancing bores located on the inside of the hub.

It has a wide operating temperature range of -30 to 100 °C There is absolutely no backlash with the frictional clamp connection.

These couplings are maintenance-free if the technical ratings are not exceeded. The bellows made of highly flexible high-grade stainless steel. See table below for hub materials.

Brief overloads are acceptable up to 1.5 times the value specified. This coupling can handle speeds up to 10,000 rpm, in excess of 10,000 available with a finely balanced version.

Custom designs with varied tolerances, key-ways, non-standard material, bellows and ATEX designs are available upon request.

The BK2 is easy to mount and well suited for space restricted installations, with a low moment of inertia rating.

BK2 Series Variants

*See above picture for reference

| Item | Torque(Nm) | Length (mm) | Fit Length (mm) | I.D. possible Ø - Ø H7 (mm) | O.D. (mm) | MomentInertia | Weight (kg) | TorsionStiffness | Axial(mm) | Lateral(mm) | Angular(deg) | AxialSpringStiffness(N/mm) | LateralSpringStiffness(N/mm) | Fastening screw | Torque (Screw) | Distance (mm) F | Distance (mm) G | Hub Material |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BK2-15 | 15 | 59 | 66 | 99 | 22 | 8-28 | 49 | 0,06 | 0,07 | 0,08 | 0,16 | 20 | 15 | 14 | 1 | 2 | 3 | 0,15 | 0,2 | 1 | 1|1,5|2 | 25 | 15 |84 | 475 | 137 | 140 | M5 | 8 | 17 | 6,5 | Aluminium-optional steel |

| BK2-30 | 30 | 69 | 77 | 113 | 27 | 10-30 | 55 | 0,12 | 0,13 | 0,14 | 0,26 | 39 | 28 | 27 | 1 | 2 |3 | 0,2 | 0,25 | 1 | 1|1,5|2 | 50 | 30 | 118 | 900 | 270 | 224 | M6 | 15 | 19 | 7,5 | Aluminium-optional Steel |

| BK2-60 | 60 | 83 | 93 |130 | 31 | 12-35 | 66 | 0,32 | 0,35 | 0,4 | 0,48 | 76 | 55 | 54 | 1,5 | 2 | 3 | 0,2 | 0,25 | 1 | 1|1,5|2 | 72 | 48 | 165 | 1200 | 420 | 337 | M8 | 40 | 23 | 9,5 | Aluminium-optional Steel |

| BK2-80 | 80 | 94 | 106 | 143 | 36 | 14-42 | 81 | 0,8 | 0,85 | 0,9 | 0,8 | 129 | 85 | 84 | 2 | 3 | 4 | 0,2 | 0,25 | 1 | 1|1,5|2 | 48 | 32 | 144 | 920 | 290 | 401 | M10 | 50 | 27 | 11 | Aluminium-optional Steel |

| BK2-150 | 150 | 95 | 107 | 144 | 36 | 19-42 | 81 | 1,9 | 2 | 2,1 | 1,85 | 175 | 110 | 97 | 2 | 3 | 4 | 0,2 | 0,25 | 1 | 1|1,5|2 | 82 | 52 | 130 | 1550 | 435 | 500 | M10 | 70 | 27 | 11 | Steel-optional Aluminium |

| BK2-200 | 200 | 105 | 117 | 163 | 41 | 22-45 | 90 | 3,2 | 3,4 | 3,6 | 2,65 | 191 | 140 | 135 | 2 | 3 | 4 | 0,25 | 0,3 | 1 | 1|1,5|2 | 90 | 60 | 280 | 2040 | 610 | 750 | M12 | 120 | 31 | 12,5 | Steel-optional Aluminium |

| BK2-300 | 300 | 111 | 125 | 200 | 43 | 24-60 | 110 | 7,6 | 7,9 | 8,3 | 4 | 450 | 350 | 340 | 2,5 | 3,5 | 4,5 | 0,25 | 0,3 | 1 | 1|1,5|2 | 105 | 71 | 605 | 3750 | 1050 | 1200 | M12 | 130 | 39 | 13 | Steel-optional Aluminium |

| BK2-500 | 500 | 133 | 146 | 169 | 51 | 35-60 | 124 | 14,3 | 14,6 | 14,8 | 6,3 | 510 | 500 | 400 | 2,5 | 3,5 | 4,5 | 0,3 | 0,35 | 1 | 1|1,5|2 | 70 | 48 | 85 | 2500 | 840 | 614 | M16 | 200 | 41 | 16,5 | Steel-optional Aluminium |

| BK2-800 | 800 | 140 | 179 | 45 | 40-75 | 134 | 16,2 | 17 | 5,7 | 780 | 711 | 3,5 | 4,5 | 0,35 | 1 | 1,5 | 2 | 100 | 285 | 2000 | 1490 | 2x M16 | 250 | 2x48 | 18 | Steel |

| BK2-1500 | 1500 | 166 | 230 | 55 | 50-80 | 157 | 43 | 45 | 11,5 | 1304 | 1180 | 3,5 | 4,5 | 0,35 | 1 | 1,5 | 2 | 320 | 440 | 3600 | 1700 | 2x M20 | 470 | 2x55 | 22,5 | Steel |

| BK2-4000 | 4000 | 225 | 85 | 50-90 | 200 | 165 | 28,8 | 3400 | 3,5 | 0,4 | 1,5 | 565 | 6070 | 2x M24 | 1200 | 2x65 | 28 | Steel |

| BK2-6000 | 6000 | 252 | 107 | 60-140 | 253 | 495 | 49,4 | 5700 | 3 | 0,4 | 1,5 | 1030 | 19200 | 2x M24 | 1200 | 2x90 | 35 | Steel |

| BK2-10000 | 10000 | 288 | 129 | 70-180 | 303 | 1214 | 80,9 | 10950 | 3 | 0,4 | 1,5 | 985 | 21800 | 2x M30 | 2400 | 2x117 | 42 | Steel |

Have Questions? Call Us!

Toll Free: (877) 799-9400Quick Quote: Get Quote

Email: sales@dpbrowntech.com

© 2026 dp Technologies Group. All rights reserved.