BK6 | Metal Bellows Coupling

Conical Sleeve And Tapered Press-Fit Connection

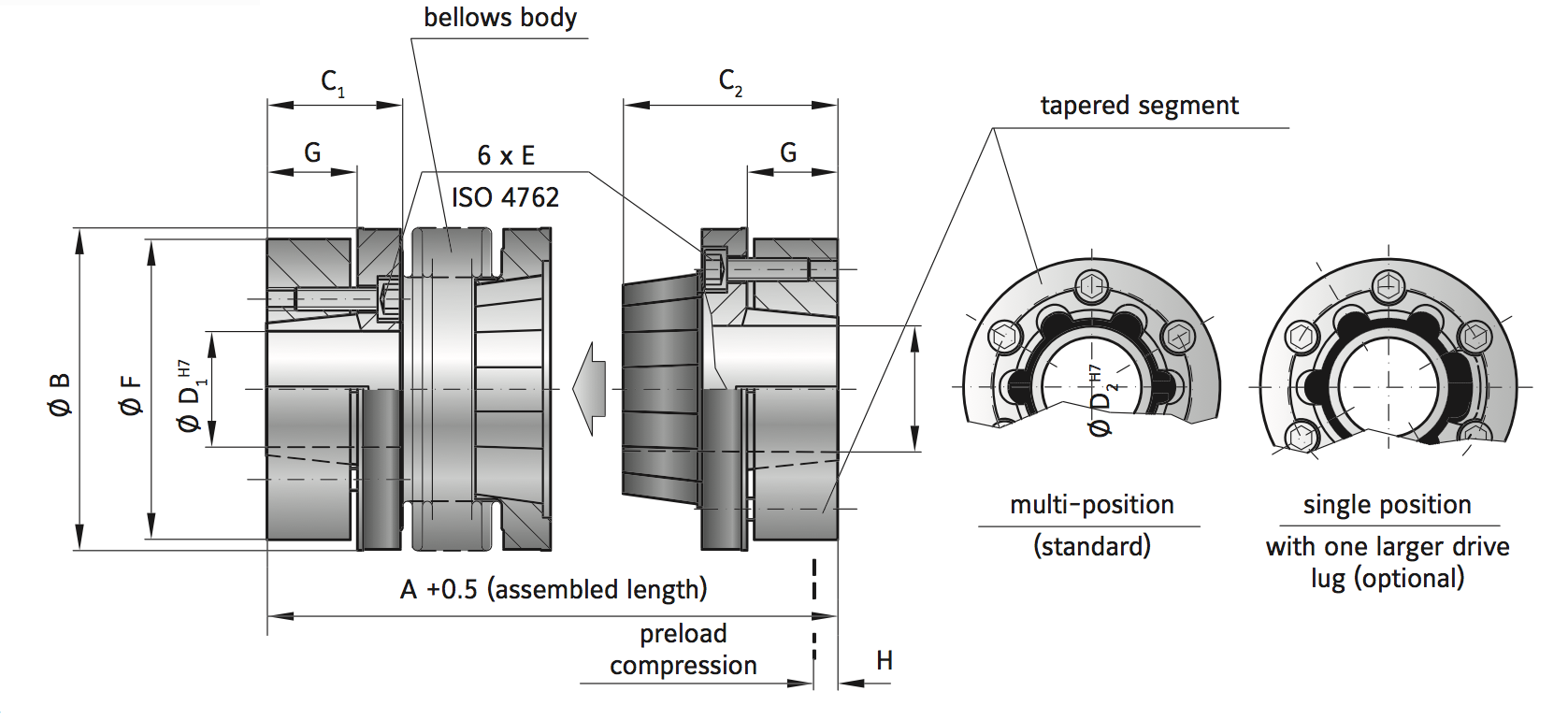

The BK6 is designed so that one side has a conical sleeve with six fastening screws

(ISO 4762) and three draw-off threads,

while the other side has a backlash-free tapered conical sleeve with a press

fit connection and 3 draw-off screws.

It has a wide operating temperature range (-30 to 100 °C) and is thermally and electrically insulated.

This is an easily mounted, backlash free solution.

BK6 bellows couplings are maintenance-free and have an infinite life, if the tolerances are not exceeded.

They are rated for speeds up to 10,000 RPM and higher speed versions (Finely Balanced) are available. Brief overloads of 1.5 times the indicated value are acceptable with these couplings.

Bellows are made of highly flexible, high-grade stain

less steel while the conical sleeves and tapered segment on bellows face are made of steel.

The tapered segment consists of glass-fiber

rein forced plastic that is molded onto a steel hub face for a wear-free connection and a high degree of operating dependability.

*Custom designs with varied tolerances, key-ways, non-standard

material and bellows are available upon request.

BK6 Series Variants

*See above picture for reference

| Item | Torque(Nm) | Length (mm) | I.D. D1 (mm) | I.D. D2 | O.D. (mm) | MomentInertia | Weight (kg) | TorsionStiffness | Lateral(mm) | Angular(deg) | LateralSpringStiff(N/mm) | Fastening screw | Torque (Screw) | Mount Length (mm) | Mount Length (mm) | PreLoad | Axial Rec Force (N) | Axial(mm) | Clamp Diameter | Clamp Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BK6-15 | 15 | 58 | 65 | 10-22 | 10-22 | 49 | 0,1 | 0,12 | 0,3 | 0,32 | 10 | 8 | 0,15 | 0,2 | 1 | 1,5 | 475 | 137 | M4 | 3,5 | 13,5 | 29 | 0,2-1,0 | 20 | 12 | 0,5 | 1 | 46,5 | 9,5 |

| BK6-30 | 30 | 68 | 76 | 12-24 | 12-24 | 55 | 0,2 | 0,25 | 0,5 | 0,52 | 20 | 14 | 0,2 | 0,25 | 1 | 1,5 | 900 | 270 | M5 | 6,5 | 21,5 | 34 | 0,5-1,0 | 50 | 30 | 0,5 | 1 | 51 | 10,5 |

| BK6-60 | 60 | 79 | 89 | 12-32 | 12-32 | 66 | 0,4 | 0,45 | 0,82 | 0,84 | 38 | 28 | 0,2 | 0,25 | 1 | 1,5 | 1200 | 420 | M5 | 8 | 18 | 39 | 0,5-1,5 | 70 | 45 | 0,5 | 1 | 60 | 11,5 |

| BK6-150 | 150 | 97 | 109 | 15-40 | 15-40 | 81 | 2,0 | 2,5 | 1,6 | 1,7 | 88 | 55 | 0,2 | 0,25 | 1 | 1,5 | 1550 | 435 | M6 | 12 | 23,5 | 49,5 | 0,5-1,5 | 82 | 52 | 1 | 2 | 74 | 17,5 |

| BK6-300 | 300 | 113 | 127 | 24-56 | 24-56 | 110 | 5,4 | 6,1 | 4,1 | 4,2 | 225 | 175 | 0,25 | 0,3 | 1 | 1,5 | 3750 | 1050 | M8 | 30 | 27 | 59 | 0,5-1,5 | 157 | 106 | 1,5 | 2 | 102 | 20 |

| BK6-500 | 500 | 132 | 145 | 30-60 | 30-60 | 124 | 8,4 | 9,1 | 6,0 | 6,3 | 255 | 245 | 0,3 | 0,35 | 1 | 1,5 | 2500 | 840 | M8 | 32 | 32 | 68 | 1,0-2,0 | 140 | 96 | 2,5 | 3,5 | 114 | 23 |

| BK6-800 | 800 | 140 | 40-62 | 40-62 | 133 | 17,5 | 8,1 | 400 | 0,35 | 1,5 | 2000 | M10 | 55 | 42 | 74 | 1,0-2,0 | 400 | 3 | 126 | 27 |

| BK6-1500 | 1500 | 158 | 50-75 | 50-75 | 157 | 44 | 16,2 | 660 | 0,35 | 1,5 | 3600 | M12 | 110 | 53 | 90,5 | 0,5-1,5 | 650 | 2 | 146 | 32 |

Have Questions? Call Us!

Toll Free: (877) 799-9400Quick Quote: Get Quote

Email: sales@dpbrowntech.com

© 2026 dp Technologies Group. All rights reserved.