ST1 | Torque Limiting Coupling

With Key-Way Connection

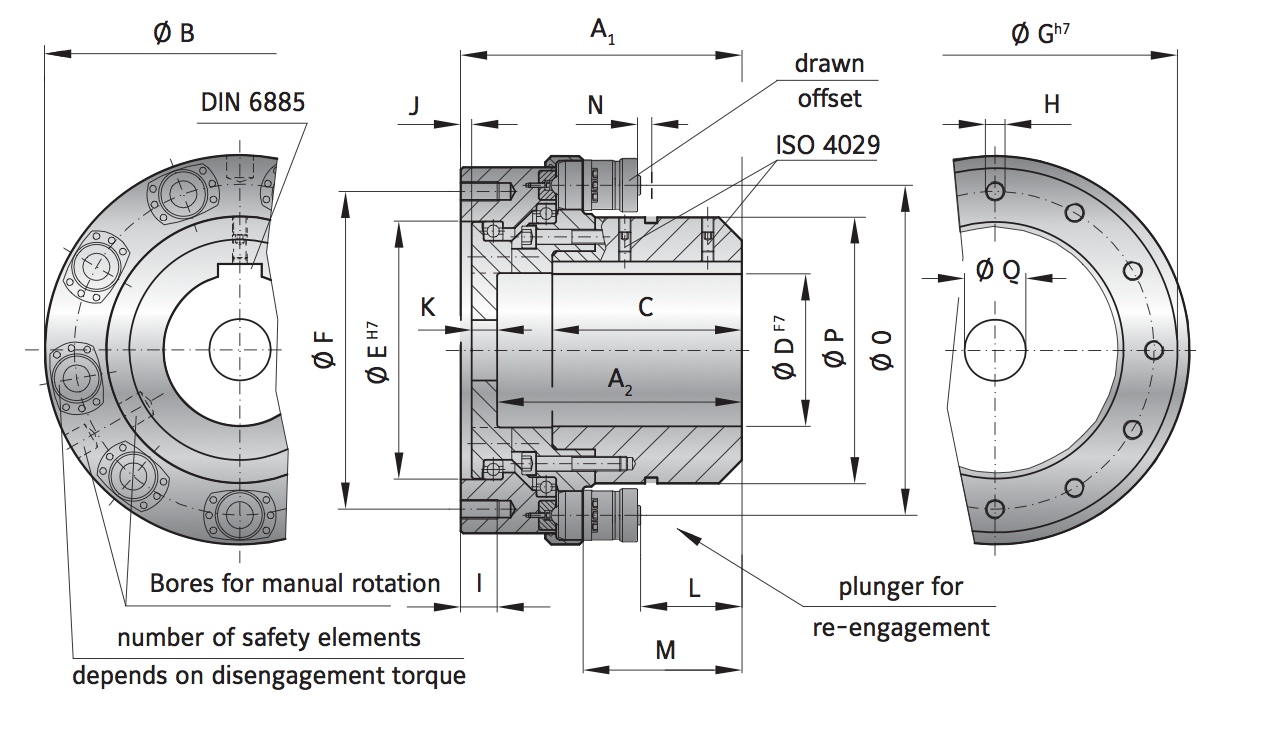

The ST1 features a coupling hub with key-way connection or spline profile on the drive side and an output flange with 12x fastening threads on the driven side.

The torque limit is field adjustable (within the selected range) and the ST1 has a rated operating temperature range of -30 to 120 °C (-22 to 248 °F).

Made from high-strength nitro-carburized steel, it is maintenance free, with an infinite life span when operated within the technical specifications. This simple, torsionally rigid and compact coupling delivers precise overload protection.

TORQUE LIMITING COUPLING

WITH KEYWAY CONNECTION

FOR INDIRECT DRIVES

0.2 - 165 KNM

ST1 Series Variants

*See above picture for reference

| Item | Length A | Depth A2 | O.D. B | Length C | I.D. D1D2 | Pilot E | Bolt Diam F | O.D. G | Threads H | Thread Depth I | Mount Len J | Thickness K | Distance L | Distance M | Distance N | Diameter O | O.D. P | Bore Q | Adj (Tq) | Inertia1 | Inertia2 | Speed | Axial Rec Frc. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ST1-2 | 120 | 100 | 198 | 100 | 30-75 | 132 | 162 | 192 | 12xM10 | 15 | 3,5 | 15 | 10,5 | 51,5 | 3,5 | 154 | 104 | max 75 | (0,2-0,5 | 3xST10) ( 0,5-1,0 | 6xST10) (1,0-1,5 | 6xST10) | 77 | 15 | 7000 | 5 |

| ST1-5 | 150 | 124 | 220 | 121 | 40-90 | 145 | 170 | 209 | 12xM12 | 20 | 4 | 21 | 16,5 | 66,5 | 4,5 | 171 | 120 | max 90 | (0.7-2 | 3xST15) (1,2-4 | 6xST15) (3,2-5 | 6xST15) | 151 | 24 | 6000 | 10 |

| ST1-10 | 183 | 158 | 270 | 120 | 40-110 | 170 | 220 | 259 | 12xM16 | 25 | 6 | 17 | 45 | 95 | 4 | 220 | 170 | max 110 | (2-5 | 3xST15) (4-10 | 6xST15) (6-14 | 9xST15) | 360 | 40 | 4200 | 20 |

| ST1-25 | 230 | 200 | 318 | 155 | 60-140 | 210 | 260 | 298 | 12xM16 | 30 | 8 | 20 | 80 | 130 | 4 | 270 | 218 | max 140 | (6-12 | 6xST15) (9-18 | 9xST15) (15-25 | 12xST15) | 780 | 63 | 3800 | 30 |

| ST1-40 | 305 | 210 | 428 | 210 | 90-170 | 270 | 330 | 380 | 12xM20 | 35 | 8 | 28 | 102 | 170 | 7,5 | 350 | 265 | max 144 | (12-21 | 6xST30) (22-32 | 6xST30) (32-45 | 9xST30) | 3570 | 166 | 3000 | 40 |

| ST1-60 | 320 | 275 | 459 | 220 | 80-200 | 300 | 360 | 418 | 12xM20 | 35 | 8 | 30 | 99 | 167 | 7,5 | 376 | 295 | max 200 | (11-18 | 3xST 30) (22-36 | 6xST 30) (30-55 | 9xST 30) | 4600 | 179 | 2500 | 50 |

| ST1-100 | 396 | 280 | 592 | 280 | 100-250 | 390 | 464 | 530 | 12xM24 | 40 | 10 | 38 | 128 | 218 | 10 | 490 | 380 | max 216 | (24-50 | 3xST70) (45-90 | 6xST70) (80-110 | 9xST70) | 16850 | 403 | 2200 | 60 |

| ST1-160 | 410 | 360 | 648 | 290 | 100-290 | 450 | 570 | 618 | 12xM24 | 40 | 10 | 38 | 135 | 225 | 10 | 532 | 418 | max 290 | (25-55 | 3xST 70) (50-110 | 6xST 70) (80-165 | 9xST 70) | 24600 | 463 | 2000 | 100 |

| ST1-250 | 600 | 740 | 361 | 370 | 200-340 | 508 | 600 | 680 | 12xM36 | 60 | 12 | 78 | 273 | 349 | 10 | 630 | 508 | max 290 | (100-170 | 8xST71) (160-250 | 12xST71) | 61300 | 850 | 1800 | 240 |

Have Questions? Call Us!

Toll Free: (877) 799-9400Quick Quote: Get Quote

Email: sales@dpbrowntech.com

© 2026 dp Technologies Group. All rights reserved.