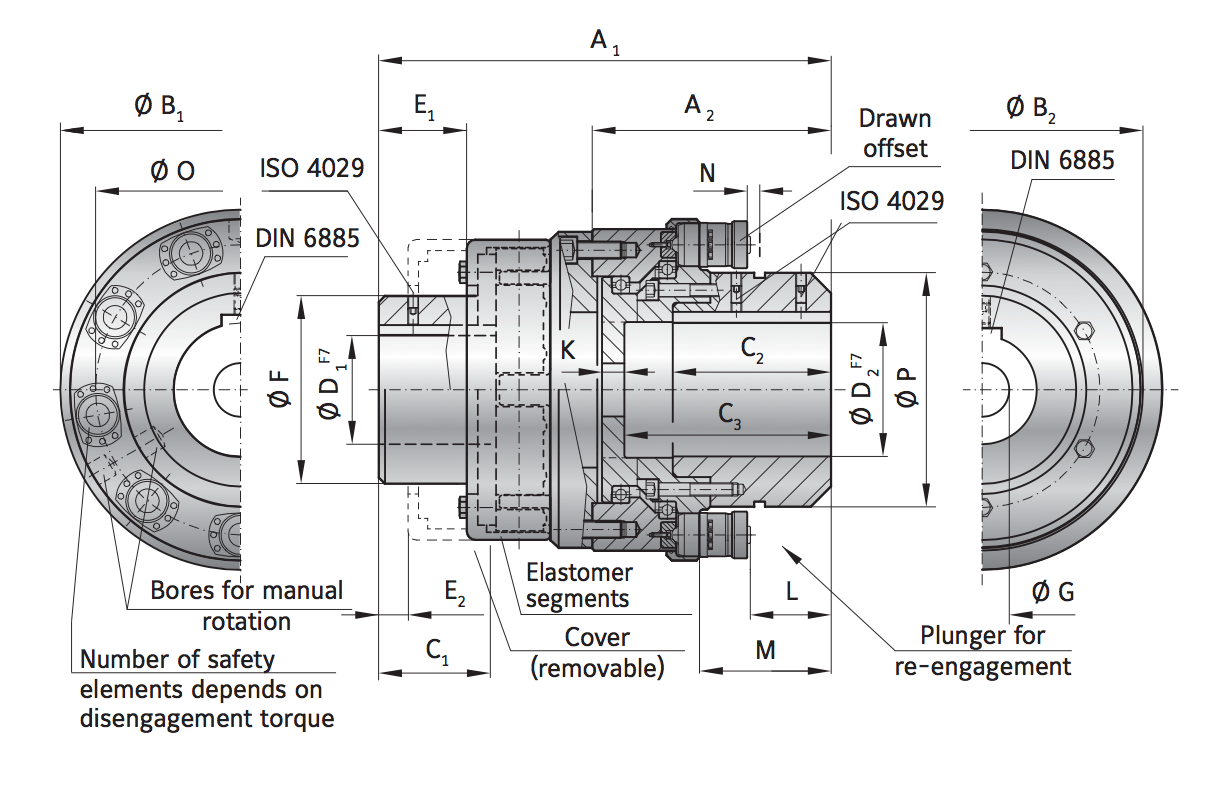

ST2 | Torque Limiting Coupling

For Direct Drives

The ST2 Mounts axially with a key-way or spline connection. Precision molded elastomer segments provide axial, lateral, and angular misalignment compensation.

They are made from a vibration damping, wear resistant rubber compound (75-80 Shore A).

Field adjustable torque modules are evenly spaced around the circumference, delivering precise overload protection. Coupling hubs are made from high-strength cast steel (coated) while the torque limiter is High-strength, nitro-carburized steel.

Standard balancing is G16, (higher speeds upon request).

This coupling has an infinite, maintenance free service life when operated within the technical specifications.

INDUSTRIAL TORQUE LIMITER

WITH INTEGRAL ELASTOMER JAW COUPLING

FOR DIRECT DRIVES

0.2 - 165 KNM

ST2 Series Variants

*See above picture for reference

| Item | Length A1 | Length A2 | O.D. B1 | O.D. B2 | O.D. | Length C1 | Length C1 | Length C2 | Bore C3 | Bore D1 | Bore D2 | Length E1 | Length E2 | Distance F | Bore G | Distance M | Distance N | Diameter O | O.D. P | Inertia1 | Inertia2 | Speed | Axial | Lateral | Angular | Torsion Stiff |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ST2-2 | 264 | 120 | 198 | 221 | 82 | 100 | 100 | 30-80 | 30-75 | 65 | 24 | 130 | max 75 | 10,5 | 51,5 | 3,5 | 154 | 104 | (0,2-0,5 | 3xST10) (0,5-1,0 | 6xST10) (1-1,5 | 6xST10) | 152 | 29 | 3400 | 1,5 | 0,3 | 1 | 58 |

| ST2-5 | 313 | 150 | 220 | 250 | 89 | 121 | 124 | 40-100 | 40-90 | 70 | 23 | 145 | max 90 | 16,5 | 66,5 | 4 | 171 | 120 | (0.7-2 | 3xST15) (1.2-4 | 6xST15) (3.2-5 | 6xST15) | 289 | 43,7 | 3000 | 1,5 | 0,4 | 1 | 92 |

| ST2-10 | 360 | 183 | 270 | 290 | 97 | 120 | 158 | 40-105 | 40-110 | 70 | 22 | 160 | max 110 | 45 | 95 | 4 | 220 | 170 | (2-5 | 3xST15) (4-10 | 6xST15) (6-14 | 9xST15) | 854 | 93 | 2400 | 1,5 | 0,4 | 1 | 145 |

| ST2-25 | 437 | 230 | 318 | 330 | 116 | 155 | 200 | 60-130 | 60-140 | 87 | 26 | 200 | max 140 | 83 | 130 | 4 | 270 | 218 | 6-12 | 6xST15) (9-18 | 9xST15) (15-25 | 12xST15) | 1850 | 115 | 2000 | 1,5 | 0,5 | 1 | 230 |

| ST2-40 | 565 | 305 | 428 | 432 | 160 | 170 | 170 | 90-160 | 90-170 | 113 | 39 | 113 | max 39 | 255 | 170 | 7,5 | 350 | 265 | (6-14 | 3xST30) (12-24 | 6xST30) (20-40 | 9xST30) | 6010 | 271 | 1800 | 2 | 0,6 | 1 | 500 |

| ST2-60 | 580 | 320 | 459 | 432 | 160 | 220 | 275 | 80-160 | 80-200 | 112 | 39 | 225 | max 200 | 99 | 167 | 7,5 | 376 | 295 | (11-18 | 3xST 30) (22-36 | 6xST 30) (30-55 | 9xST 30) | 8960 | 287 | 1800 | 2 | 0,6 | 1 | 580 |

| ST2-100 | 716 | 396 | 592 | 553 | 230 | 280 | 280 | 100-200 | 100-250 | 152 | 65 | 152 | max 65 | 300 | 218 | 10 | 490 | 380 | (24-50 | 3xST70) (45-90 | 6xST70) (80-100 | 9xST70) | 21890 | 642 | 1500 | 2,5 | 0,7 | 1 | 850 |

| ST2-160 | 730 | 410 | 648 | 553 | 230 | 290 | 360 | 100-200 | 100-290 | 152 | 65 | 300 | max 290 | 135 | 225 | 10 | 532 | 418 | (25-55 | 3xST 70) (50-110 | 6xST 70) (80-165 | 9xST 70) | 36858 | 729 | 1500 | 2,5 | 0,7 | 1 | 1000 |

Have Questions? Call Us!

Toll Free: (877) 799-9400Quick Quote: Get Quote

Email: sales@dpbrowntech.com

© 2026 dp Technologies Group. All rights reserved.