ST4 | Torque Limiting Coupling

For Direct Drives

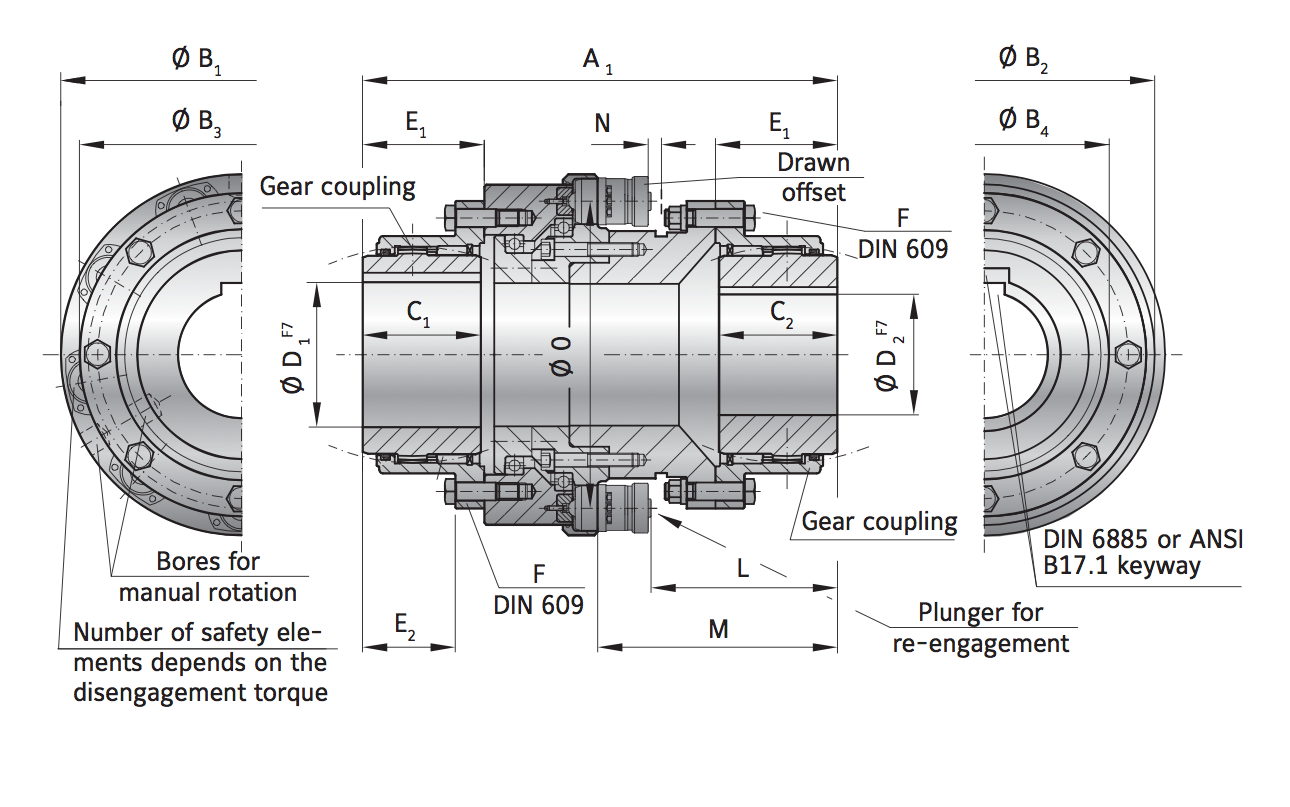

The ST4 Mounts with a key-way or spline connection. An integral gear coupling provides axial, lateral, and angular misalignment compensation.

Gear coupling ends feature extremely wear resistant tooth geometry made from high-strength alloyed steel.

Field adjustable torque modules are evenly spaced around the circumference, delivering high torque density and precise overload protection. The torque limiter is made from High-strength, nitro-carburized steel.

It has a rated operating temperature range of -30 to 120 °C (-22 to 248 °F) and standard balancing is G16, (higher speeds upon request).

This is a robust coupling with an infinite, maintenance free service life when operated within the technical specifications.

INDUSTRIAL TORQUE LIMITER

WITH INTEGRAL GEAR COUPLING

FOR DIRECT DRIVES

2 - 165 KNM

ST4 Series Variants

*See above picture for reference

| Item | Length A1 | O.D. B1 | O.D. B2 | O.D. B3 | O.D. | Length C1/2 | Bore C3 | Bore D1/2 | Length E2 | TQ F | Fastener F | Distance M | Distance N | Diameter O | O.D. P | Inertia1 | Inertia2 | Speed | Axial | Angular |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ST4-2 | 280 | 198 | 192 | 168 | 130,5 | 62 | 30-78 | 63,5 | 18 | 6xM8 | 110 | 148 | 3,5 | 154 | (0,2-0,5 | 3xST10) (0,5-1,0 | 6xST10) (1,0-1,5 | 6xST10) | 108 | 2,5 | 4000 | 1,5 | 2x0,35 deg |

| ST4-5 | 350 | 220 | 209 | 200 | 158,4 | 76 | 32-98 | 78,5 | 65 | 10xM12 | 138 | 188 | 4,5 | 171 | (0,7-2 | 3xST15) (1,2-4 | 6xST15) (3,2-6 | 6xST15) | 244 | 45 | 3900 | 2,5 | 2x0,35 deg |

| ST4-10 | 390 | 270 | 259 | 225 | 183,4 | 90 | 42-112 | 92,5 | 65 | 12xM12 | 159,5 | 209,5 | 4,5 | 220 | (2-5 | 3xST 15) (4-10 | 6xST 15) (6-14 | 9xST 15) | 529 | 65 | 3700 | 2,5 | 2x0,35 deg |

| ST4-25 | 460 | 318 | 300 | 265 | 211,5 | 105 | 46-132 | 108 | 150 | 12xM16 | 202 | 252 | 4,5 | 270 | (6-12 | 6xST15) (9-18 | 9xST15) (15-25 | 12xST15) | 1117 | 100 | 3550 | 3 | 2x0,35 deg |

| ST4-40 | 580 | 428 | 399 | 330 | 275,5 | 135 | 60-174 | 139 | 150 | 14xM16 | 238 | 306 | 8 | 350 | (12-21 | 6xST30) (22-32 | 6xST30) (32-45 | 9xST30) | 4363 | 225 | 2750 | 4 | 2x0,35 deg |

| ST4-60 | 650 | 459 | 418 | 370 | 307 | 150 | 70-190 | 154 | 220 | 14xM18 | 275 | 343 | 8 | 376 | (11-18 | 3xST 30) (22-36 | 6xST 30) (30-55 | 9xST 30) | 6650 | 293 | 2420 | 4 | 2x0,35 deg |

| ST4-100 | 780 | 592 | 560 | 438 | 367 | 190 | 110-233 | 194 | 400 | 14xM22 | 318 | 408 | 10 | 490 | (24-50 | 3x ST70) (45-90 | 6x ST70) (80-110 | 9x ST70) | 20611 | 570 | 1950 | 4 | 2x0,35 deg |

| ST4-160 | 860 | 648 | 618 | 525 | 423 | 220 | 120-280 | 225 | 520 | 16xM24 | 360 | 450 | 10 | 532 | (25-55 | 3xST 70) (50-110 | 6xST 70) (80-165 | 9xST 70) | 33820 | 718 | 1730 | 5 | 2x0,35 deg |

| ST4-250 | 1060 | 740 | 724 | 639 | 553 | 290 | 200-340 | 296 | 670 | 22xM24 | 458 | 534 | 10 | 630 | (100-170 | 8xST71) (160-250 | 12xST71) | 84926 | 1280 | 950 | 6 | 2x0,35 deg |

Have Questions? Call Us!

Toll Free: (877) 799-9400Quick Quote: Get Quote

Email: sales@dpbrowntech.com

© 2026 dp Technologies Group. All rights reserved.