ER Series | Servo Motor Motion Control

The ER Series motors by Exlar are explosion-proof motors rated for Class 1, div 1, Groups B, C, and D. These actuators are

suitable when the air may contain flammable vapors in concentrations high enough to create a risk of a explosive or ignitable atmosphere.

Group B includes atmospheres where hydrogen or similar gases, such as manufactured gas, may be present. Group C includes ethyl-ether,

ethylene or cyclopropane. Group D includes atmospheres where gasoline, alcohol, acetone, butane, hexane, naphtha, benzene, benzol,

lacquer solvent vapors, or natural gas may be present. (ER series motors are not recommended for acetylene atmospheres.)

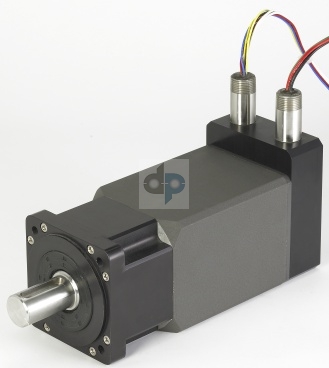

The Exlar ER Series features a brushless, permanent magnet motor with an integrated planetary gear reducer. The planetary gear

reduction offers high torque and high reliability with low backlash. The ER Series motor is compatible with any servo drive

control system. The Exlar SV Series digital servo control system is particularly well-matched for the ER Series motor. The ER Series

motors feature a unique winding design that results in a highly efficient and durable motor with higher torque than other

similarly sized motors.

Group B includes atmospheres where hydrogen or similar gases, such as manufactured gas, may be present. Group C includes ethyl-ether,

ethylene or cyclopropane. Group D includes atmospheres where gasoline, alcohol, acetone, butane, hexane, naphtha, benzene, benzol,

lacquer solvent vapors, or natural gas may be present. (ER series motors are not recommended for acetylene atmospheres.)

The Exlar ER Series features a brushless, permanent magnet motor with an integrated planetary gear reducer. The planetary gear

reduction offers high torque and high reliability with low backlash. The ER Series motor is compatible with any servo drive

control system. The Exlar SV Series digital servo control system is particularly well-matched for the ER Series motor. The ER Series

motors feature a unique winding design that results in a highly efficient and durable motor with higher torque than other

similarly sized motors.

ER Series Ordering Information

| ERAAA-BBB-CDF-GGG-HHH-II-JJJ-{XX-#####} | ||

|---|---|---|

| ER = Model Series | AAA = Frame Size | BBB= Gear Reduction Ratio |

| 115 = 115 mm | (Optional) When reduction ratio is ommitted, unit is a motor only, no gearhead. | |

| 004 = 4:1 Single Reduction | ||

| C = Shaft Type | DDD = Connector Options | 005 = 5:1 Single Reduction |

| K = Keyed | N## = Potted NPT with flying leads | 010 = 10:1 Single Reduction |

| R = Smooth/Round | ## = Length of flying leads in feet | 016 = 16:1 Double Reduction |

| X = Special Shaft | 020 = 20:1 Double Reduction | |

| F = Brake Options | 025 = 25:1 Double Reduction | |

| S = Standard, no brake | 040 = 40:1 Double Reduction | |

| 050 = 50:1 Double Reduction | ||

| 100 = 100:1 Double Reduction | ||

| GGG = Feedback Options (Please indicate the amplifier to be used to power the motor.) | ||

| XX1 = Custom Feedback Mount - purchaser must supply dawing of feedback device and desired wiring drawings. | ||

| 001 = Standard Feedback Mount - actuator is supplied ready for size 15 resolver, includes .375 mm shaft. | ||

| 002 = Standard Feedback Mount - actuator is supplied ready for size 15 resolver, includes 8 mm shaft. | ||

| AB6 = Allen Bradley 13941 (resolver) (replaces AB2) | ||

| API = API resolver based (resolver) | ||

| AM3 = Advanced Motion Controls (resolver) | ||

| BD2 = Baldor Flex Series (resolver) (replaces BD1) | ||

| BM2 = Baumueller bmaXX & BUM series (resolver) | ||

| BO1 = Bosch (resolver) | ||

| CC1 = Cleveland Machine Controls (resolver) | ||

| CM1 = Comau P{ICO (resolver) | ||

| CS1 = Custom Servo Motors MPA, MPSL (resolver) | ||

| EL1 = Elmo Motion Control (resolver) | ||

| EX4 = Exlar SV2000 Series (resolver) (replaces EX3) | ||

| IN4 = Indramat ECO Drive, Standard resolver (resolver) (replaces IN3) | ||

| KM1 = Kollmorgen Servostar and Servostar CD Series 230V2 (resolver) | ||

| KM5 = Kollmorgen Servostar 600 Series 460V2 (resolver) (replaces KM2) | ||

| LZ5 = Lenze 9300 Series (resolver) | ||

| MD1 = Modicon (resolver) | ||

| MX1 = Metronix ARS Series Amplifiers (resolver) | ||

| OR1 = Ormec (resolver) | ||

| PC1 = Parker Compumotor Apex & Z Series (resolver) | ||

| PC7 = Parker Compumotor Compax 3 (resolver) | ||

| PC0 = = Parker Compumotor with resolver, Parker PS connectors (resolver) | ||

| PS3 = Pacific Scientific SC900, 700 Series (resolver) (replaces PS1) | ||

| SM2 = Siemens (resolver) (replaces SM1) | ||

| SP2 = In Motion PAM Series (resolver) | ||

| WD1 = Whedco (resolver) | ||

| HHH = Motor Magnet Stacks | ||

| 1A8 = 1 stack, 24 Vrms, 8 pole | 2A8 = 2 stack, 24 Vrms, 8 pole | 338 = 3 stack, 230 Vrms, 8 pole |

| 1B8 = 1 stack, 48 Vrms, 8 pole | 2B8 = 2 stack, 48 Vrms, 8 pole | 358 = 3 stack, 400 Vrms, 8 pole |

| 118 = 1 stack, 115 Vrms, 8 pole | 218 = 2 stack, 115 Vrms, 8 pole | 368 = 3 stack, 460 Vrms, 8 pole |

| 138 = 1 stack, 230 Vrms, 8 pole | 238 = 2 stack, 230 Vrms, 8 pole | |

| 158 = 1 stack, 400 Vrms, 8 pole | 258 = 2 stack, 400 Vrms, 8 pole | |

| 168 = 1 stack, 400 Vrms, 8 pole | 268 = 2 stack, 460 Vrms, 8 pole | |

| II = Speed Designators | ||

| 01-99 = Two digit number. Rated speed in rpm x 100 | ||

| JJ = Hazardous Location Temperature Rating | ||

| T3A = 180 degree C (Samariam Cobalt magnets) | ||

| T4 = 135 degree C (Neodymium-Iron-Boron magnets) | ||

| XX = Optional Mechanical Designations | ||

| XL = Special lubrication | ||

© 2026 dp Technologies Group. All rights reserved.