Parker R7 RIPPED Ironcore linear motors, with their patented anti-cog technology, produce the large forces needed for many industrial applications – without the roughness associated with traditional ironcore linear motors.

Parker R7 RIPPED Ironcore linear motors, with their patented anti-cog technology, produce the large forces needed for many industrial applications – without the roughness associated with traditional ironcore linear motors.

With continuous forces ranging from 40 N (9 lbf) up to 90 N (20 lbf) and peak forces ranging from 190 N (43 lbf) up to 325 N (73 lbf), the RIPPED family is well suited for a broad range of extremely demanding applications.

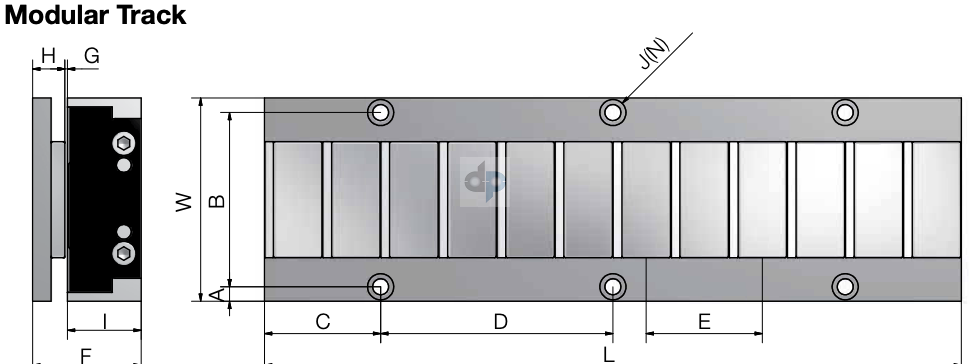

Parker offers modular magnet tracks for unrestricted travel length.

The RIPPED motor connector modules allow quick and easy installation while reducing overall maintenance costs.

Ultra-high-flex cables come standard.

Virtually cog-free operation combined with powerful ironcore technology make the RIPPED family of motors a superior choice for affordable high-force and ultrasmooth motion.

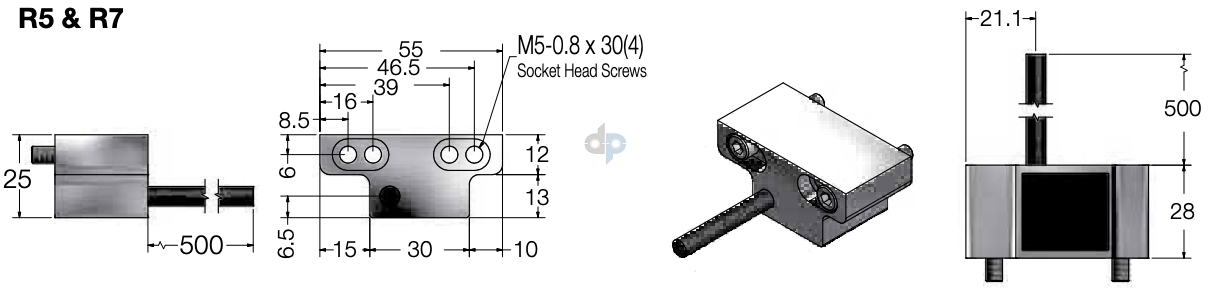

Ironcore motors consist of a forcer which rides over a single magnet track.

The forcer is made of copper windings wrapped around iron laminations.

The back iron provides an efficient path for the magnetic flux to circulate between the motor and the magnet rail.

In addition, there is an efficient path for heat to escape the motor.

This ironcore design allows for extremely high forces and efficient cooling.

In fact, the ironcore design offers the highest force available per unit volume.

Finally, the ironcore design is economically attractive because only one row of magnet material is required.

Parker has developed a patented anti-cog technology that virtually eliminates cogging and allows ironcore motors to be used in applications where only ironless motors were considered before.

This offers the machine builder a powerful combination of extremely high force and smooth operation in an economical package.

*See the tables below for the various lengths of Magnet Track available and

Electrical Specifications for the RIPPED Ironcore R7 Linear Motor.

| Model | L | W | A | B | C | D | E | F | G | H | I | J (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R7-160MN | 160 | 70 | 5 | 60 | 40 | 80 | 40 | 37.5 | 1 | 11.1 | 25.4 | M5 Socket Head Screw (4) |

| R7-240MN | 240 | 70 | 5 | 60 | 40 | 80 | 40 | 37.5 | 1 | 11.1 | 25.4 | M5 Socket Head Screw (6) |

HS Type Hall Sensor

| Model | ContFrc | Feedback | ContAmpPk | PeakFrc | PeakAmp | OHM | Inductance | MagneticAttr | PeakPwr | ContPwr | Winding |

|---|---|---|---|---|---|---|---|---|---|---|---|

| R7-1 | 154 | Digital Hall Sensor | 4.6 | 587 | 21 | 4 | 6.1 | 1557 | 3600 | 180 | S |

| R7-2 | 308 | Digital Hall Sensor | 4.6 | 1174 | 21 | 8 | 12.2 | 3114 | 7200 | 360 | S |

| R7-2 | 308 | Digital Hall Sensor | 9.3 | 1174 | 42 | 2 | 3.1 | 3114 | 7200 | 360 | P |

| R7-3 | 462 | Digital Hall Sensor | 4.6 | 1761 | 21 | 12 | 18.3 | 4761 | 10800 | 540 | S |

| R7-3 | 462 | Digital Hall Sensor | 14 | 1761 | 63 | 1.33 | 2 | 4761 | 10800 | 540 | T |

© 2026 dp Technologies Group. All rights reserved.